Smart SCC control drives higher ROI in dairy operations by directly improving productivity and profitability. Lower somatic cell counts lead to more milk per cow and greater net income. Technology, such as a somatic cell count tester, enables rapid detection and response. Consultancy and supply chain visibility play a vital role in maximizing return on investment.

| Benefit | Description |

|---|---|

| Improved Decision-Making | Real-time access to data enables informed choices and proactive responses to disruptions. |

| Cost Savings | Enhanced planning reduces reliance on expedited shipping and optimizes inventory management. |

| Enhanced Risk Management | Predictive analytics help identify and mitigate risks before they escalate. |

Key Takeaways

- Lower somatic cell counts lead to higher milk production and increased profits. Focus on effective SCC control to boost your dairy operation’s ROI.

- Utilize technology like somatic cell count tester for real-time data. This helps in making informed decisions and improving herd management.

- Invest in staff training to enhance efficiency. Well-trained employees can quickly respond to herd health changes, leading to better outcomes.

- Implement cost management strategies by tracking detailed expenses. Regular reviews can identify areas for savings and profit improvement.

- Adopt process automation to reduce manual labor and errors. Automation increases productivity and allows employees to focus on more valuable tasks.

ROI with SCC Control

Why ROI Matters in SCC Control?

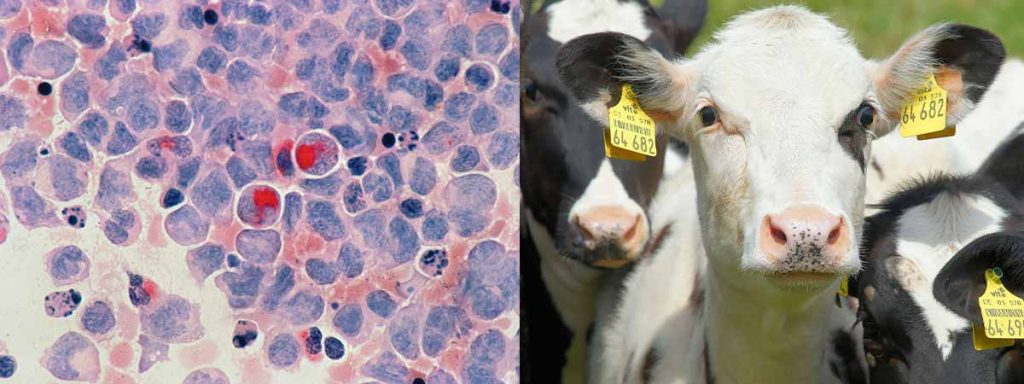

ROI stands as a critical measure in dairy production. Producers monitor SCC control because it directly affects financial outcomes. High somatic cell count often signals herd health problems. These issues lead to lower milk yields and higher costs for mastitis treatment. When SCC control is effective, dairy farms see measurable operational and strategic benefits.

A comparison between high-performing and low-performing herds shows the impact on ROI:

| Metric | Best-Third Herd | Worst-Third Herd | Difference |

|---|---|---|---|

| Bulk Tank SCC (cells/mL) | 134,000 | 284,000 | 152,000 |

| Milk Production (pounds/cow/day) | 11 | N/A | N/A |

| Net Farm Income per Cow | $159 | N/A | N/A |

Farms with lower somatic cell count earn more per cow. They also avoid financial losses from quality premiums, market access issues, and increased treatment costs. The economic impact extends to the supply chain. Penalties for high SCC can reduce profitability, while premiums for low SCC boost ROI.

Dairy operations face average economic losses of $533 per farm due to high SCC. Most losses come from discarded milk, which accounts for nearly 90% of total losses. These numbers highlight why roi matters in scc control.

Technology’s Role in ROI

Technology transforms how dairy farms achieve ROI. Early adopters of artificial intelligence and automation report significant gains. For example, some operations see a 42% increase in ROI and a 30% reduction in call handling times. These improvements come from better data management and faster decision-making.

Modern platforms, such as AI-powered systems, help farms make better decisions quickly. They also save staff time and improve satisfaction. SD-WAN technology increases network agility and reduces costs, which supports efficient SCC control.

Consultancy adds value by optimizing workflows and providing ongoing training. This approach ensures that technology investments align with business goals. Proper setup and maintenance of tools improve cash flow and reduce errors. These strategies maximize return on investment and sustain long-term roi growth.

Key ROI Strategies for SCC Control

Cost Management Approaches

Cost management forms the foundation of effective ROI strategies in SCC control. Many companies focus on manufacturing and distribution costs but often overlook the total supply chain cost. This oversight can lead to missed opportunities for roi optimization. Using overly aggregated standard costs sometimes results in misleading conclusions about cost-effectiveness. Farms that track detailed costs across the supply chain make better investment decisions and improve financial outcomes.

- Farms should break down costs into specific categories, such as feed, labor, veterinary care, and milk quality penalties.

- Regular reviews of these categories help identify areas for cost reduction and profit improvement.

- Accurate cost tracking supports better business planning and aligns with long-term strategy.

Continuous monitoring and adjustment of cost management practices ensure that dairy operations maximize ROI and maintain financial stability.

Process Automation Benefits

Process automation delivers significant ROI for dairy businesses. Automation reduces reliance on manual labor, which lowers staffing costs and minimizes errors. Automated systems shorten cycle times, increasing throughput and overall productivity. These improvements translate into higher profit margins.

- Automated workflows ensure compliance with industry regulations, reducing the risk of fines and penalties.

- Employees can focus on meaningful tasks, which boosts job satisfaction and retention.

- Faster processes lead to improved customer experiences, as clients receive quicker responses and higher-quality products.

- Early adopters of automation gain a competitive advantage by adapting to market changes more efficiently.

Automation supports continuous improvement and helps businesses sustain long-term ROI growth.

Data-Driven Decisions with Somatic Cell Count Tester

Data-driven decision-making stands at the core of ROI optimization in SCC control. The somatic cell count tester provides real-time data that enables early detection of mastitis, compliance with quality standards, and enhanced herd management. Farms that use these tools can track each cow’s udder health history and evaluate the effectiveness of mastitis control procedures.

| Improvement Area | Evidence |

|---|---|

| Early detection of mastitis | Detecting infections early means less antibiotic use, lower treatment costs, and reduced milk loss. |

| Compliance with quality standards | Regular monitoring ensures compliance with national and international milk regulations. |

| Increased profitability | Farmers get better prices for high-quality milk with low SCC levels. |

| Enhanced herd management | Some testers integrate with herd management software, allowing you to track each cow’s udder health history. |

| Reduced milk waste | Regular SCC testing ensures that only high-quality milk is sold or processed. |

A monthly summary of somatic cell count score on milk samples from each cow provides valuable feedback on mastitis control strategies. This approach supports better financial performance and helps maximize roi.

Staff Training for ROI

Staff training plays a vital role in achieving high ROI in SCC control. Well-trained employees understand how to use technology, follow best practices, and respond quickly to changes in herd health. Training programs should cover the use of somatic cell count tester, data interpretation, and process automation tools.

- Regular training sessions keep staff updated on new technologies and procedures.

- Employees who receive ongoing education contribute to higher efficiency and better customer service.

- Training reduces errors and supports continuous improvement, which leads to greater profit and financial stability.

Investing in staff development aligns with business goals and ensures that dairy operations maintain a strong return on investment.

Investment and Optimization in SCC Control

Aligning Technology and Business Strategy

CIOs who align technology with business strategy deliver faster innovation and higher ROI. They synchronize IT investments with enterprise objectives and build strong partner ecosystems. This approach uses Return on Objectives (ROO) metrics to connect technology spending to strategic goals. Companies that define enterprise-wide objectives for tech investments see better ROI outcomes. They optimize costs and achieve more with less, especially through AI-driven efficiency. Effective data governance reduces operational costs and improves decision-making. Strategic alignment also manages risks from new technologies and ensures security. Improved customer experiences result from technology initiatives that meet specific needs. Sixty-six percent of C-suite executives view GenAI as a game changer for ROI. However, eighty-nine percent worry about security risks, showing the need for careful alignment.

Leveraging Supply Chain Visibility

Supply chain visibility boosts roi by improving reliability and reducing costs. Farms that track issues to their source respond faster to problems. They gain a comprehensive view of product quality and supplier performance. Consistent standards and continuous improvement across teams support better ROI. Streamlined quality control assignments increase efficiency. Supplier autonomy builds trust and improves performance. Lower costs come from informed decisions at every supply chain step. The table below shows how supply chain metrics drive roi:

| Metric | Benefit Description |

|---|---|

| On-Time-In-Full (OTIF) | Higher OTIF improves reliability and customer satisfaction. A 3% increase in OTIF can improve revenue by 1%. |

| Inventory Turnover | Optimized inventory levels lead to faster turnover and improved cash flow. |

| Lead Time Reduction | Shorter lead times result from identifying bottlenecks. |

| Cost Savings | Reduced shipping costs, fewer stockouts, and less waste. |

| Supply Chain Resilience | Quick recovery from disruptions ensures business continuity. |

| Net Present Value (NPV) | Considers the time value of money for better financial planning. |

Companies have realized the critical importance of investing in the supply management function. The roi metric indicates that allocating those resources is smart business. Strategic supplier relationship management can lead to more efficient product design and materials, resulting in lower commodity and production costs.

Continuous Improvement for ROI

Continuous improvement methods help sustain roi in SCC control. Lean Management uses tools like 5S, Kanban, and Value Stream Mapping. Six Sigma applies DMAIC and Statistical Process Control. Kaizen focuses on Gemba Walks and PDCA cycles. Total Quality Management uses customer feedback and process improvement teams. These methods support ongoing financial gains and profit growth. Farms that use these strategies see better roi calculator results and make smarter investment decisions. They also improve soil health through regular soil assessment, which increases profit and supports long-term return on investment. Up-front capital investment in these methods leads to measurable financial benefits and stronger ROI calculator outcomes.

| Methodology | Key Tools and Techniques |

|---|---|

| Lean Management | 5S, Kanban, Value Stream Map, Daily meetings, Leader Standard Work, Catchball, Hoshin Kanri, SIPOC diagrams, Poka-Yoke, Fishbone diagrams |

| Six Sigma | DMAIC, Statistical Process Control, 5 Whys, SIPOC diagrams, Poka-Yoke, Fishbone diagrams |

| Kaizen | Gemba Walk, PDCA, Mind Mapping, Kaizen events |

| Total Quality Management | Fishbone diagrams, Quality circles, Customer feedback systems, Process improvement teams |

A strong ROI calculator helps track progress and ensures that every improvement supports business and customer needs.

Calculate ROI in SCC Control

ROI Formula Explained

ROI measures the effectiveness of SCC control investments. The standard formula calculates roi by dividing net profit by total investment cost and multiplying by 100. This approach helps dairy farms understand the financial gains from adopting new technology or improving processes. The formula applies to many scenarios, including the use of a somatic cell count tester. Farms use this calculation to compare different strategies and make informed investment decisions.

ROI Formula:

ROI = (Net Profit / Investment Cost) × 100

The process involves determining total revenue generated from the investment, calculating all related expenses, and subtracting costs from revenue to find net profit. Farms then apply the ROI formula to see the percentage return on investment.

| Step | Description |

|---|---|

| 1 | Determine the total revenue generated from the investment. |

| 2 | Calculate the total cost of investment, including all related expenses. |

| 3 | Compute net profit by subtracting total costs from total revenue. |

| 4 | Apply the ROI formula: (Net Profit / Investment Cost) × 100. |

Step-by-Step Calculation Example

A dairy farm invests in a somatic cell count tester to improve milk quality. The farm tracks the financial impact over one year.

- Total Revenue: $15,000 from increased milk sales and quality premiums.

- Total Cost of Investment: $5,000 for the somatic cell count tester and training.

- Net Profit: $15,000 – $5,000 = $10,000.

- ROI Calculation: ($10,000 / $5,000) × 100 = 200%.

This result shows that the farm doubled its investment. The returns include higher grain yields, improved soil health from better herd management, and increased customer satisfaction. The farm uses this roi calculation to guide future investment decisions and refine its strategy.

Key Metrics to Track

Tracking key metrics helps farms sustain ROI and maximize returns. These indicators support ongoing financial analysis and business optimization.

- Net profit from SCC control investments

- Total cost of technology and process improvements

- Revenue growth from higher milk quality and grain yields

- Soil assessment results for herd health impact

- Customer satisfaction scores

- Operational efficiency rates

- Return on investment and return on mission alignment

Organizations also measure success using the return on mission framework. This approach evaluates how investments support business goals, operational efficiency, and social responsibility. Farms that monitor these metrics achieve stronger financial gains and maintain long-term ROI.

Overcoming Challenges in SCC Control Investment

Implementation Barriers

Many dairy operations face obstacles when investing in SCC control. These barriers can slow progress and reduce roi. The most common challenges include poor communication, lack of trust, and limited management involvement. Farms also struggle with inconsistent performance measurement and weak training programs. The table below outlines these barriers:

| Barrier Description |

|---|

| Lack of communication for sustainable standards and regulations |

| Lack of trust between manufacturer and supplier |

| Lack of scope and focus for sustainable collaboration |

| Unwillingness to share risks and rewards |

| Lack of top management involvement |

| Lack of combined training programs |

| Lack of consistent and adequate performance measurement systems |

Successful farms address these issues by building strong partnerships and involving leadership in every step. They create clear standards and invest in joint training. These actions help improve roi and support better investment decisions.

Ensuring Data Accuracy

Accurate data plays a key role in maximizing ROI. Farms must collect reliable information on herd health, milk quality, and soil conditions. They use advanced tools to monitor performance and track changes over time. Staff receive training to handle data correctly and avoid errors. Regular audits help maintain high standards. Accurate records support better business planning and increase profit. They also help farms meet customer expectations and comply with regulations.

Sustaining ROI Long-Term

Long-term roi requires a clear strategy and ongoing effort. Farms set financial goals that match their desired return on investment and risk tolerance. They create budgets that support regular investments and savings. Teams review results often and adjust plans to match market trends. Farms focus on soil health, customer satisfaction, and operational efficiency. These steps help maintain profit and business growth. Farms that follow this approach see steady roi and stronger financial outcomes.

- Goal setting for clear financial targets

- Budgeting and saving for regular contributions

- Review and adjustment based on market trends and goals

Tip: Farms that track roi and adjust their strategy regularly stay ahead in the market.

Best Practices for Maximizing ROI

Building a Smart SCC Control Plan

A smart SCC control plan starts with a clear strategy that aligns with business goals. Farms assess capacity requirements by looking at current production and future market demand. They identify bottlenecks that could slow down operations. Scenario planning helps teams prepare for changes in production needs. Dynamic resource allocation ensures that the right people and machines work where they add the most value. Farms sequence production orders to reduce setup times and increase throughput. Tracking machine and labor utilization reveals areas for improvement. Integration with ERP systems connects production with demand forecasts. Just-in-time inventory management reduces excess stock and lowers costs. The table below outlines essential components of a smart SCC control plan:

| Aspect of Capacity Planning | Description |

|---|---|

| Accurate Evaluation of Capacity Requirements | Assessing current and future production capabilities based on market demand and production goals. |

| Identification of Bottlenecks and Constraints | Analyzing to identify potential bottlenecks that could impede production. |

| Scenario Planning and ‘What-If’ Analysis | Exploring various production scenarios to optimize resource allocation. |

| Dynamic Resource Allocation | Assigning resources based on skill sets and availability to maximize ROI. |

| Optimal Sequencing of Production Orders | Ensuring the sequence of production orders minimizes setup times and maximizes throughput. |

| Tracking and Analysis of Utilization | Monitoring machine and labor utilization to identify improvement opportunities. |

| Integration with ERP Systems | Aligning production with demand forecasts through integration with ERP systems. |

| Just-in-Time Inventory Management | Incorporating JIT techniques to reduce carrying costs associated with excess inventory. |

Leveraging Advanced Features

Advanced features in SCC control systems help farms achieve higher roi. Automated alerts notify staff about changes in somatic cell counts. Data analytics tools provide insights into herd health and milk quality. Farms use these features to make better investment decisions and improve profit. Soil monitoring tools track the impact of herd management on soil health. Integration with customer management systems ensures that farms meet customer expectations. Farms that use advanced features see gains in efficiency and financial performance.

Farms that track and measure ROI after implementing new features can identify areas of value and justify further investments.

Regular Review and Adjustment

Regular review and adjustment keep ROI high over time. Teams monitor key metrics such as net profit, customer satisfaction, and soil health. They analyze results and adjust plans to match business goals. Continuous evaluation supports better financial outcomes and helps farms stay competitive. Farms that review their strategy often can respond quickly to market changes. They maintain strong roi and deliver consistent value to customers.

- Set regular review periods for all SCC control processes.

- Use data to guide adjustments and improve efficiency.

- Align every change with long-term business and financial goals.

Conclusion

Maximizing ROI in SCC control requires a clear focus on practical steps. Successful organizations often:

- Invest in technology to streamline workflows and improve decision-making.

- Empower employees through training and resources.

- Monitor performance by tracking key metrics and adjusting as needed.

Continuous improvement remains essential for sustained ROI. Organizations that track roi and cost savings can identify high-cost areas and prioritize improvements. Aligning technology with business strategy ensures that every investment supports long-term roi growth. Regular roi tracking helps maintain profitability and competitiveness.

FAQ

What Is SCC Control?

SCC control refers to managing somatic cell counts in dairy herds. Lower SCC means healthier cows and higher milk quality. Farms use technology and best practices to monitor and reduce SCC levels.

How Does SCC Control Improve ROI?

SCC control increases milk yield and quality. Farms earn more from premium milk and spend less on treatments. Effective SCC management leads to higher profits and better business outcomes.

Which Technologies Help with SCC Control?

Farms use somatic cell count tester, data analytics tool, and automation system. These technologies provide real-time data, support early detection, and streamline herd management.

Why Is Staff Training Important in SCC Control?

Staff training ensures proper use of technology and adherence to best practices. Well-trained employees detect issues early and respond quickly. This leads to better herd health and higher ROI.

What Metrics Should Farms Track for SCC ROI?

Farms should track net profit, investment costs, milk quality, and customer satisfaction. Monitoring these metrics helps measure success and guides future improvements.